Siding

Siding

Angi is the easy way to book services and compare quotes form highly rated pros near you. Compare multiple top-rated local pros. Enter your zip & get multiple bids, fast. Estimates In Minutes. Local & Trusted Pros. Always Free To Use. Project Cost Guides. Instant Pro Matching. Shop Local Offers. Comprehensive Cost Guides. Background Checked Pros. 5-Star Rated Pros.

All About Siding

Our company was founded on the belief that every home should reflect the individual styles and personalities of its homeowners. Whether adding a deck for cozy get-togethers or building an addition to make room for a new family member, JMH Home Improvements is dedicated to helping you create your dream home environment.

Built from the ground up, JMH began his carpentry business as an entrepreneurial adventure. With his innate ability to create masterpieces from scratch, JMH Home Improvements quickly developed into a successful family business.

Since founding JMH Home Improvements, JMH continues to dedicate his time and resources to making every client happy with each finished product. Services have expanded to include all levels of home improvements, repairs and enhancements – designing decks, finishing basements, building custom furniture and much more. The unique skill set and hands-on experience JMH brings to every project is unmatched.

Common Siding Materials

- Wood Siding Stile

For a long time wood was the only choice for siding. Despite new materials like vinyl and cement, wood is the traditional choice and also one of the most versatile. From cedar shingles and live edge clapboard to pieces from a reclaimed barn, you have an abundance of choices for wood siding and it’s probably the most eco-friendly material. One downside is that it won’t resist fire very well, and the constant exposure to weather means it usually needs a bit more maintenance than metal or vinyl. Over time it fades to a gray color, but you can always paint or stain it.

- Metal Siding Stile

Although not as common, using a metal material for siding has its own advantages. For one, it won’t burn, which is something to consider. On the other hand, it dents more easily than other materials. As for the type of metal, the most common seems to be corrugated aluminum, although steel is often used as well. Depending on where it’s sourced, metal can be a “green” option. One downside is that it can rust, something that happens much more in a salty environment. We notice a growing number of houses using a combination of wood and metal siding, blending contemporary and rustic, which makes for an interesting look.

Although not as common, using a metal material for siding has its own advantages. For one, it won’t burn, which is something to consider. On the other hand, it dents more easily than other materials. As for the type of metal, the most common seems to be corrugated aluminum, although steel is often used as well. Depending on where it’s sourced, metal can be a “green” option. One downside is that it can rust, something that happens much more in a salty environment. We notice a growing number of houses using a combination of wood and metal siding, blending contemporary and rustic, which makes for an interesting look.

- Vinyl Siding Stile

The favorite choice among cookie-cutter houses, and most homes across America, vinyl is known for its durability and low maintenance. You can find all sorts of colors and designs to mimic traditional shingles, clapboard and any other popular style. While it might cost a bit more than other materials, it will last a very long time. Given its plastic appearance, many homeowners opt for something with a bit more personality and authenticity. Given the hand-built nature of many tiny houses, where sustainability and resourcefulness takes center stage, we don’t see vinyl used very often and that’s a good thing in our opinion.

The favorite choice among cookie-cutter houses, and most homes across America, vinyl is known for its durability and low maintenance. You can find all sorts of colors and designs to mimic traditional shingles, clapboard and any other popular style. While it might cost a bit more than other materials, it will last a very long time. Given its plastic appearance, many homeowners opt for something with a bit more personality and authenticity. Given the hand-built nature of many tiny houses, where sustainability and resourcefulness takes center stage, we don’t see vinyl used very often and that’s a good thing in our opinion.

Siding or wall cladding is the protective material attached to the exterior side of a wall of a house or other building. Along with the roof, it forms the first line of defense against the elements, most importantly sun, rain/snow, heat and cold, thus creating a stable, more comfortable environment on the interior side. The siding material and style also can enhance or detract from the building’s beauty. There is a wide and expanding variety of materials to side with, both natural and artificial, each with its own benefits and drawbacks. Masonry walls as such do not require siding, but any wall can be sided. Walls that are internally framed, whether with wood, or steel I-beams, however, must always be sided..

- Wood Shingle Stile

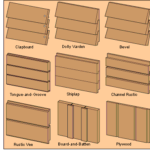

Jointed horizontal siding (also called “drop” siding or novelty siding) may be shiplapped or tongue and grooved (though less common). Drop siding comes in a wide variety of face finishes, including Dutch Lap (also called German or Cove Lap) and log siding (milled with curve).

Vertical siding may have a cover over the joint: board and batten, popular in American wooden Carpenter Gothic houses; or less commonly behind the joint called batten and board or reversed board and batten.

You wont find to many people that are a Master at all four different parts of the trade or know everything there is to know about carpentry. But you will find people who are a Master Journeyman in at least one maybe two of these categories.

Education-In the carpentry trade it takes at least 4 years of school and on the job training to become a certified skilled Journeyman. Within the four years apprentices are taught how to use power tools hand tools at the beginning. Then apprentices are taught to frame walls sheetrock do drop ceilings and concrete forms. Later they will learn how to read blue prints and have some leadership training.